Dry soil mixing is a ground improvement technique that improves soft, high moisture clays, peats, and other weak soils, by mechanically mixing them with dry cementitious binder.

Common uses

Process

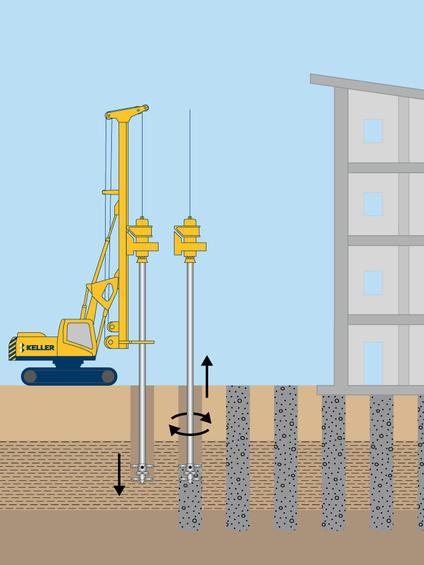

To construct the columns, a high-speed drill advances a drill rod with radial mixing paddles near the bottom of the drill string into the ground. During penetration, the tool shears the soils to prepare them for mixing. After the tool reaches the design depth, the binder is pumped pneumatically through the drill steel to the tool, where it is mixed with the soil as the tool is withdrawn.

The dry soil mixing process constructs individual columns, rows of overlapping columns, or 100% mass stabilisation, all with a designed strength and stiffness.

Advantages

Quality assurance

Quality is controlled and assured through column installation protocols and the results of relevant laboratory and field-verification tests. Each column is provided with a chart-log, which typically comprises: element identification, mixing tool details, mixing depth, mixing time, binder dosage, injection flow rate and pressure, total mass of binder added, mixing tool velocities and rpm during penetration and withdrawal.

The mixing energy and binder content is calculated from this information to match design requirements.

Specimens of stabilised soils for testing are usually obtained from fresh columns with a push sampler.

Advanced core drilling and other field-testing methods can also be used to obtain specimens and to inspect the continuity, uniformity and stiffness of deep soil mixing columns. The selection of suitable verification methods depends on their relevance, accuracy and applicability in relation to the purpose and pattern of soil treatment and design properties of stabilised soil.